Rear Tractor Tire PSI: Maximize Fuel Efficiency and Soil Health

Many farmers underestimate the impact of proper tire pressure on their bottom line and the long-term health of their soil. Optimizing rear tractor tire pressure isn't just about pumping up tires; it's about achieving a delicate balance that significantly impacts fuel efficiency, soil compaction, and tire longevity. This guide provides a step-by-step approach to mastering this crucial aspect of sustainable agriculture. For more detailed information on filling tractor tires, see this helpful resource: filling guide.

Understanding the Importance of Proper Tire Pressure

Your tractor tires are the interface between your machinery and the land. Incorrect tire pressure creates a ripple effect across your entire operation. Overinflation (too much air) concentrates the tractor's weight on a small area, leading to significant soil compaction. This hinders water infiltration, root growth, and overall soil health, resulting in reduced crop yields. Conversely, underinflation (too little air) causes increased tire slippage, leading to higher fuel consumption and accelerated tire wear. Think of it like driving a car with low tires – you're working harder to achieve less and wasting valuable resources.

Finding Your Ideal PSI: A Step-by-Step Guide

While finding the optimal PSI might seem straightforward, it's more nuanced than simply inflating tires to maximum capacity. The ideal pressure depends on various factors including load, speed, and soil conditions.

Step 1: Consult Your Owner's Manual: The most crucial step lies in consulting your tractor's operator's manual or the manufacturer's website. This usually contains a load/inflation table guiding you on the appropriate PSI based on your load and intended speed.

Step 2: Identify Your Most Demanding Application: Determine the most demanding condition your tractor typically faces – this isn't necessarily the heaviest load you carry but the combination of weight, speed, and terrain that puts the most stress on your tires (typically pulling a heavy load uphill in muddy conditions).

Step 3: Determine Your Base PSI: Use the load/inflation table to find the recommended pressure for your most demanding application. This is your baseline.

Step 4: Adjust for Terrain and Conditions: Use your judgment to adjust the PSI based on current conditions. Softer, wetter soil might require slightly lower pressure to minimize compaction, whereas harder, drier ground may allow for slightly higher pressures to improve efficiency and reduce slippage.

Step 5: Always Check When Tires Are Cold: Tire pressure increases as tires heat up due to friction. Always check and adjust tire pressure when the tires are cold (ideally, first thing in the morning) for accurate readings.

Step 6: Establish a Regular Inspection Schedule: Implement a regular check and adjustment plan (weekly or even daily during peak seasons) to maintain optimal tire pressure.

Real-World Success: Case Study – John's Experience

John, a farmer from Iowa, initially neglected proper tire pressure management. He experienced high fuel bills and inconsistent crop yields. After implementing a routine tire pressure check and adjustment, he noted a 15% reduction in fuel costs and a consistent 5% increase in crop yields within one year. Furthermore, his tire lifespan increased significantly thanks to reduced wear and tear.

Advanced Techniques and Considerations

Precision Agriculture Technology: Modern technology offers sensors and farm management software that monitor tire pressure in real-time and even adjust it automatically for optimal performance.

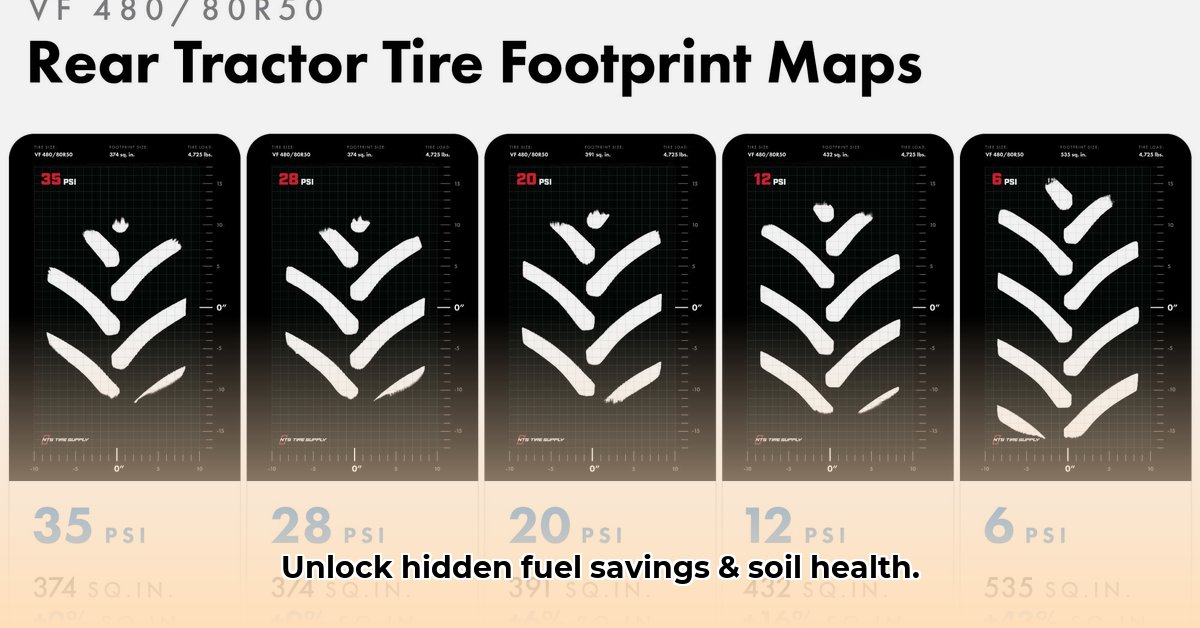

Low-Pressure Tires: These offer a larger footprint, reducing soil compaction and improving traction, but represent a significant upfront investment.

Tire Maintenance: Regular tire inspections, rotations, and maintenance extend their lifespan and maximize benefits from correctly adjusted pressure.

Weighing Your Options: Different Approaches to Tire Pressure Management

Proper tire pressure management involves several strategies. The best method depends on various factors, including technology resources and operational needs:

| Strategy | Advantages | Disadvantages |

|---|---|---|

| Following Manufacturer's Recommendations | Simple, reliable baseline for most conditions | Requires careful calculation and might not address all situations precisely. |

| Simplified PSI Charts | Quick reference for daily adjustments. | Less precise, may not cover diverse soil types or work conditions. |

| Precision Agriculture Technology | Real-time monitoring and automatic adjustments for optimal performance. | High initial cost, reliance on technology. |

How to Optimize Tractor Tire Pressure for Minimal Soil Compaction and Fuel Efficiency: Key Takeaways

Minimizing Soil Compaction: Maintaining optimal tire pressure is crucial for minimizing soil compaction. Under-inflation significantly exacerbates soil compaction, resulting in reduced water infiltration, root growth, and a compromised soil structure.

Maximizing Fuel Efficiency: Correct inflation minimizes tire slippage, directly translating to higher fuel efficiency and reduced operational costs.

Extended Tire Lifespan: Proper inflation reduces uneven wear and tear, extending the overall lifespan of your tractor tires, thus reducing replacement costs.

This guide provides actionable steps to optimize your tractor's tire pressure and move towards sustainable and profitable farming practices. Remember, consistent monitoring and smart adjustments can yield significant long-term benefits for your operation and the environment.